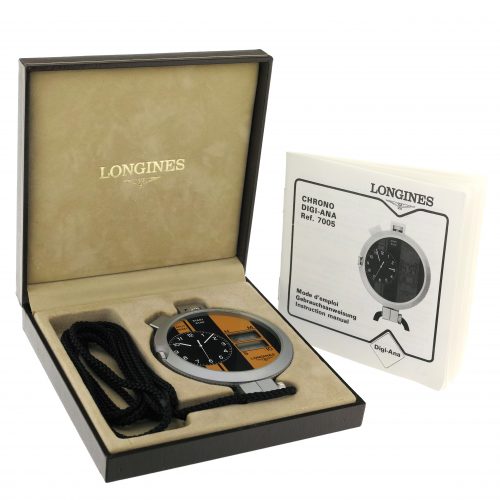

A rare and well-preserved fine NIVAROX Observatory Competition chronometer (50 mm movements category) No. 427, base on Longines cal. 260 modified by Nivarox S.A, in its original testing housing and “Bulletin de Marche”. Made in 1966 excessively for Observatory Competitions, this particular watch achieved quite a stunning results. To do it Nivarox watchmakers used a special balance on famous Nivarox spiral, removed from the movement everything that could affect on the accuracy (even time setting gears was removed to reduce the friction!) and of course spent months of fine adjustments.

The icing on the cake is the original “Bulletin de Marche” issued from the Observatory of Neuchatel in Dec. 1969 which accompanies the unit. This chronometer was used for several competitions over the years (as usual for good examples), 1966, 1968 and 1969. The rating results were simply breathtaking, just look at the certificate.

C. Observatory testing housing made of wood, on both sides glazed, steel case, approx. Ø70mm. D. Silver with Arabic numerals, outer 1/5th seconds track, steel blued hands. M. Longines Cal. 260, modified by Nivarox SA, Geneva stripes finish, 36.000 A/h, Glucydur balance, Nivarox balance spring.

Nivarox is probably the most important company in the entire world of Swiss watch making. Now owned by the Swatch Group, Nivarox makes the vast majority of the parts that make mechanical watch movements function. Nivarox is also the trade name of the metallic alloy from which its products are fabricated. Its notable property is that its coefficient of elasticity is remarkably constant with temperature. As a trade name, Nivarox is a German acronym for “Nicht variabel oxydfest” (G.) or “Non-Variable Non-Oxidizing” (E.). The Nivarox alloy is a nickel iron alloy (Fe 54%, Ni 38%, Cr 8%, Ti 1%, Si 0.2%, Mn 0.8%, Be 0.9%, C <0.1%) used mainly in the watch industry for hairsprings for balance wheels. When used for critical watch components, the alloy reduces errors due to temperature variation. Hairsprings made of this alloy have a spring constant which does not vary with temperature, allowing the watch’s balance wheel, its timekeeping element, to keep better time.

Up until 1967, the exact length of a second was determined by the Earth’s motion around the sun, and the Neuchatel observatory’s precise optics allowed the fine measurements necessary for precise timesetting to be made. Because of this, Neuchatel began to host observatory chronometer trials – a series of the most stringent, thorough accuracy tests in the history of mechanical watchmaking. The trials, held over a period of forty-five days, encompassed ten separate movement timekeeping tests in five different positions and two temperatures. These observatory trials quickly outgrew their roots as a simple certification test, and before long the trials at Neuchatel were a competitive battleground for the finest watchmakers in Europe. Names like Longines, Zenith, Peseux, Omega and many more traded records for decades, fighting to produce the most accurate movement possible. These movements were never intended for regular use, and bore little to no resemblance to what these companies offered their consumers. Along with the technical prowess of the watchmakers building the movements, in the “racing team” there were specialists, the “regleurs de precision”, who worked tweaking a number of movements until they could find a few of them to bring to the Observatory Competitions. By means of fine adjustments, replacement of key parts, use of special lubricants, they could create a few movements for the Competitions. And often they were the same movements for many years.

Watch is in overall great condition, running and ready to use!